4

Safety Non-contact Sensors

an introduction to Safety Sensors

Imagine the powerful machines in factories and workshops running without the risk of becoming dangerous—thanks to safety sensors. In today’s automated world, safety sensors play an essential, often unseen, role. These aren’t just devices but the vigilant protectors of our workplaces, ensuring the well-being of both people and equipment.

Safety sensors detect and respond instantly when something goes wrong, reducing the risk of injury and equipment damage. They operate quietly yet effectively, constantly monitoring movements to ensure each machine stays within safe operating limits. Without them, the smooth operation of modern industrial processes would be at far greater risk from human error and mechanical issues.

In this blog, we’ll delve into various types of safety sensors, such as Inductive Proximity Sensors, Magnetic Coded Sensors, and RFID Coded Sensors. Discover how these critical components are foundational to creating a safe and efficient industrial environment.

SAFETY NON-CONTACT SWITCHES : AN OVERVIEW

Non-contact sensors, including inductive proximity sensors, magnetic coded sensors, RFID sensors, and stainless steel safety devices, are essential for detecting objects, positions, and physical changes without direct interaction, ensuring enhanced durability and minimizing mechanical wear. These technologies are particularly valuable in safety-critical environments where contact may lead to contamination, wear, or inefficiency. Inductive proximity sensors are commonly used for detecting metal objects, magnetic coded sensors ensure reliable security in tamper-sensitive areas, RFID sensors enable precise tracking and identification, and stainless steel safety devices offer exceptional resistance to corrosion, ideal for harsh or hygienic environments. Together, these solutions support a wide range of industries—from manufacturing and automation to food processing and healthcare—providing dependable monitoring of liquid levels, machine positions, object detection, and securing hazardous areas.

In industrial settings, non-contact safety sensors and stainless steel safety devices play a vital role in protecting both personnel and equipment. Frequently installed in safety doors, emergency stop systems, and machinery guards, they detect when someone or something enters a restricted zone, helping prevent accidents. When integrated with control systems, these sensors enable automated safety responses for an added layer of protection. With strong resistance to contamination, vibration, and harsh conditions, including the enhanced durability of stainless steel safety devices, they are well-suited for long-term use in demanding industrial environments.

types of non-contact safety switches

ReeR Safety Proximity Sensors – PI-Safe | Inductive Sensors

Boost Safety with PI-Safe Proximity Sensors: Certified and Reliable Proximity Sensors for Enhanced Safety.

The ReeR PI-Safe Inductive Proximity Sensor range enhances production uptime and safety by offering precise position detection in compliance with EN 60947-5-3 certification. Designed with cross-fault monitoring, it ensures both operator and machine protection. The PI-Safe Cylindrical Sensors are available in M12, M18, and M30 sizes with options for flush or non-flush mounting and feature LEDs for power and signal status indication. These sensors connect via M12 4-pole cables and are rated up to IP69K for protection. Additionally, the PI-Safe Square Sensors measure 40 x 40 x 66mm, available in flush and non-flush versions, with LEDs for power and signal status. They also connect via M12 4-pole cables and meet SIL 3 – Ple standards for high safety integrity.

PI-Safe Cylindrical Sensors

| Part Number | Material | Dimensions | Range | Operating Voltage | Safety Rating |

| PI M12 NF | Body: Stainless steel; Head: PBT | Non-flush M12 Thread 70mm length | 0.5-4mm | 19.2-30VDC | SIL 2, Pl d |

| PI M18 NF | Body: Stainless steel; Head: PBT | Non-flush M18 Thread 70.5mm length | 1-8mm | 19.2-30VDC | SIL 2, Pl d |

| PI M18 F | Body: Brass white bronze coated; Head: PBT | Flush M18 Thread 70mm length | 1-5mm | 19.2-30VDC | SIL 2, Pl d |

| PI M18 FR | Body: Brass white bronze coated; Head: PBT | Flush M18 Thread 86.5mm length | >10mm | 10-30VDC | SIL 2, Pl d |

| PI M30 NF | Body: Stainless steel; Head: PBT | Non-flush M30 Thread 70mm length | 1-15mm | 19.2-30VDC | SIL 2, Pl d |

| PI M30 F | Body: Brass white bronze coated; Head: PBT | Flush M30 Thread 70mm length | 1-10mm | 19.2-30VDC | SIL 2, Pl d |

| PI M30 NF K | Body: Stainless steel; Head: PBT | Non-flush M30 Thread 80mm length | 6-12mm | 19.2-30VDC | SIL 3, Pl e |

| Part Number | Material | Dimensions | Range | Operating Voltage | Safety Rating |

| PI SQ F-NF | Body: Diecast zinc; Head: PPE | Flush or non-flush 40 x 40 x 66mm | 10-15mm | 19.2-30VDC | SIL 3, Pl e |

| PI SQ NF | Body: Diecast zinc; Head: PPE | Non-flush 40 x 40 x 66mm | 4-20mm | 19.2-30VDC | SIL 3, Pl e |

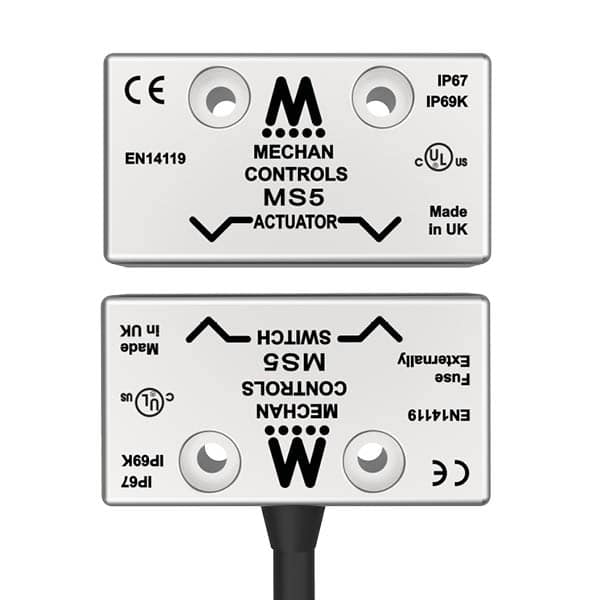

Magnetic Coded Safety Sensors: An Overview

Magnetic coded safety sensors are advanced devices engineered to monitor the positions of machinery, equipment, and access points in industrial environments. They utilize a combination of magnetic fields and unique codes to achieve precise, fail-safe detection. These sensors are primarily designed to prevent accidents, minimize downtime, and enhance overall workplace safety.

The Importance of Safety in Industry

Safety is a critical priority in industrial settings. Accidents can result in injuries, damage to equipment, and costly production delays. Implementing robust safety measures is essential to reduce these risks and ensure personnel well-being. Magnetic coded safety sensors are instrumental in achieving these safety objectives.

How Magnetic Coded Safety Sensors Work

Magnetic coded safety sensors operate on a straightforward yet highly effective mechanism, consisting of two main parts:

- Actuator: The actuator is generally attached to a moving part of the equipment, like a gate or guard. It contains magnets and coded elements that generate a specific magnetic field pattern.

- Sensor: The sensor, mounted nearby, continuously monitors the magnetic field from the actuator. As the actuator moves, the sensor detects any changes in the magnetic field and interprets the coded signal.

The sensor’s capability to identify specific magnetic codes provides high accuracy in monitoring the actuator’s position. This technology adds an extra layer of safety by preventing unauthorized access, improper machine movement, and unintentional equipment operation.

Applications of Magnetic Coded Safety Sensors

Magnetic coded safety sensors are used in various industrial applications, including:

- Machine Guarding: They monitor the status of guards, gates, or doors, ensuring that machines operate safely and stop automatically if access is compromised.

- Conveyor Systems: Integrated into conveyor systems, these sensors help regulate material flow, enhancing worker safety and system efficiency.

- Material Handling: Common in material handling equipment, they help prevent accidents and improve operational efficiency.

- Access Control: Magnetic coded safety sensors play a key role in restricting access to hazardous zones, ensuring that only authorized personnel can enter when it’s safe to do so.

RFID Coded Safety Switches

RFID Safety Switches from trusted brands like ReeR, Wieland, EUCHNER, Pizzato, and IDEM utilize RFID tags and readers to manage access control, real-time monitoring, and asset tracking. They play a crucial role in systems like Lockout-Tagout (LOTO) and emergency response, ensuring that only authorized personnel can interact with machinery. This adherence to safety standards, such as ISO 13849-1, is vital for workplace safety. These sensors provide real-time data for compliance and reporting, facilitating maintenance and repair tasks by offering valuable insights into equipment status and operational efficiency.

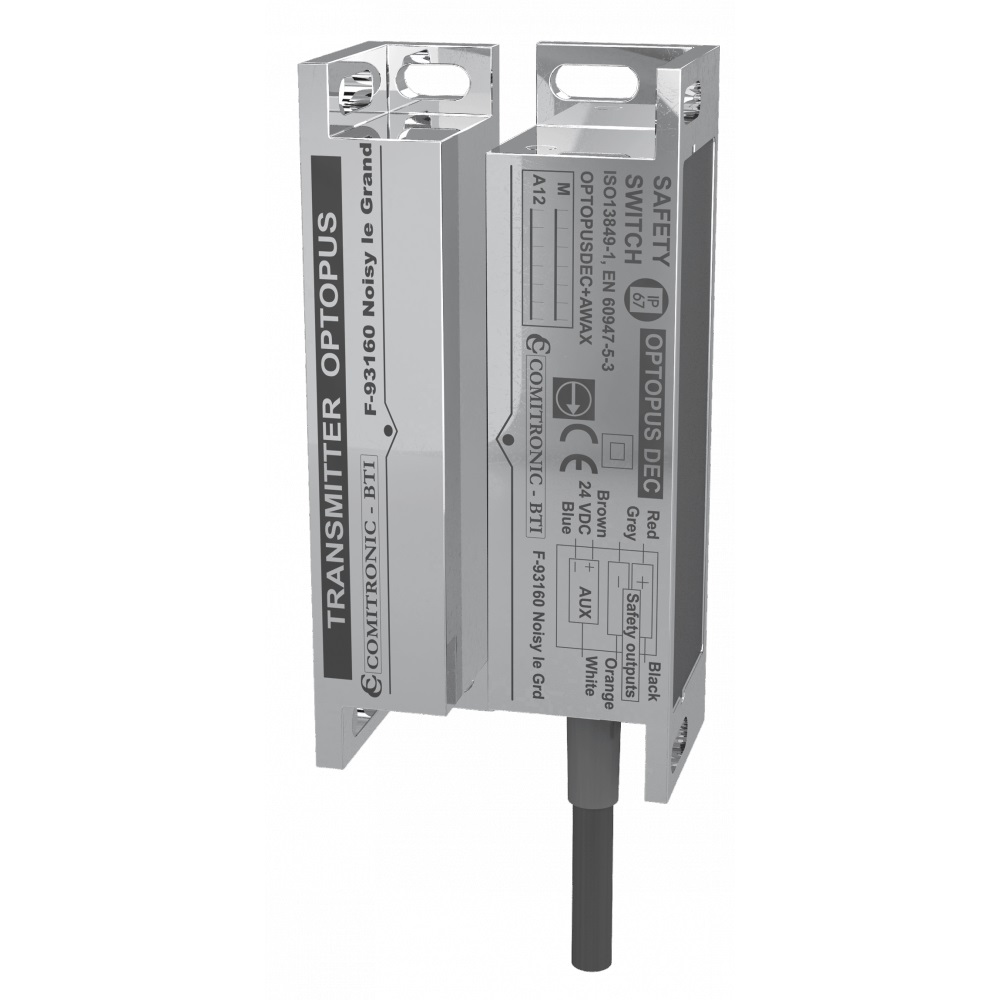

Stainless Steel Electronic

Stainless Steel Safety Devices are meticulously designed to meet stringent food-grade standards, making them ideal for the food industry, where reducing contamination risks is critical. Constructed from high-quality, non-corrosive stainless steel, these devices withstand the demanding conditions typical in food processing environments. This robust design not only extends their lifespan but also supports the hygienic requirements essential in food handling.

Featuring precise magnetically coded mechanisms, these devices provide dependable operation, safeguarding both food quality and machinery safety. By preventing accidental openings and ensuring that equipment operates safely, these safety devices play a vital role in food processing and packaging, protecting both operators and products.

Brands like Comitronic further enhance this range with advanced stainless steel safety solutions, offering seamless integration with modern hygiene standards for effortless cleaning and maintenance. Consequently, Stainless Steel Safety Devices contribute to regulatory compliance and foster a strong culture of safety and quality within food production facilities.

application

The MRFID series of RFID safety switches are designed for high-level safety applications with the flexibility for series connection while maintaining a high safety level up to PL e / SIL 3. These switches use advanced RFID technology to ensure tamper protection, allowing each sensor in a series to communicate reliably without compromising safety. MRFID sensors are available with various coding options—individual, unique, and actuator-coded—enabling tailored applications where specific coding levels are required. With IP67 and IP6K9K protection ratings, MRFID series switches are highly resistant to environmental factors, making them suitable for use in harsh conditions such as those found in the food industry, where resistance to aggressive cleaning agents is essential.

Additionally, MRFID sensors support series connection of up to 30 devices, ensuring comprehensive safety coverage across multiple points while simplifying installation and reducing wiring complexity. These features make the MRFID series an ideal choice for safeguarding machinery in environments requiring high durability and strict safety standards

Conclusion

In modern industrial environments, safety sensors are the cornerstone of reliable protection, ensuring both operational efficiency and the security of personnel. These devices play a vital role in safeguarding workers, equipment, and processes by detecting potential hazards, monitoring access, and preventing accidental operations. From magnetic coded sensors to RFID-enabled devices, safety sensors offer flexible, dependable solutions that adhere to strict safety standards, such as ISO 13849-1 and SIL 3, providing the highest levels of safety integrity. As automation and industry continue to evolve, integrating robust safety sensors will be key to creating secure, efficient, and resilient workplaces where innovation and safety work hand in hand.