PCB relays are compact, circuit board-mounted switching devices designed for reliable control in space-constrained electronic and industrial systems. These relays offer high switching capacity, low…

PCB relays are compact, circuit board-mounted switching devices designed for reliable control in space-constrained electronic and industrial systems. These relays offer high switching capacity, low power consumption, and excellent electrical isolation between control and load circuits. Available in various contact configurations and coil voltages, PCB relays are ideal for applications in automation, HVAC, lighting, and power management. Their compact footprint and dependable performance make them a key component in modern control boards and embedded systems.

Types of PCB Power Relays

Electromagnetic Relays

Electromagnetic relays are the most commonly used type in printed circuit boards (PCBs), operating through an electromagnetic coil that mechanically opens or closes contacts. These relays are widely used in industrial control systems, household appliances, and automotive systems for switching high loads using low signal voltage.

Key specs include:

- Coil voltage (e.g., 5V, 12V, 24V DC)

- Contact ratings for current and switching voltage

- Fast response times and durable mechanical components

Solid-State Relays

Solid-state relays (SSRs) use semiconductor devices instead of mechanical contacts. They offer faster switching, zero contact bounce, and longer lifespan, making them ideal for low-power components, AC control functions, or compact relay setups in sensitive electronic devices.

While more expensive than electromagnetic relays, SSRs are noise-free and provide seamless power flow in applications like lighting, HVAC, and automation.

Hybrid Relays

Hybrid relays combine the benefits of both electromagnetic and solid-state technologies. Typically, an SSR is used to trigger the load initially, while the mechanical contacts maintain conduction. This improves contact longevity and reduces coil power consumption, especially in high switching frequency scenarios.

They are ideal for lighting systems, battery energy storage systems, and building automation requiring consistent switching performance.

Thermal Relays

Thermal relays use a bimetallic strip to detect heat generated by current flow. When excessive heat indicates an overload, the relay trips to protect the circuit. These are useful in motor windings, distribution systems, and circuit breakers, especially in industrial power relays with inrush current risk.

Often paired with electromagnetic PCB relays, they provide dual protection for load circuits and power supplies.

Operational Classifications of Relays

SPST – Single Pole Single Throw Relays

SPST relays are the simplest relay type. They allow a single circuit to be connected or disconnected. These are commonly used for basic ON/OFF control in low-voltage applications and are found in compact PCBs where limited space is a concern.

SPDT – Single Pole Double Throw Relays

SPDT relays can route a single input to one of two outputs. This makes them ideal for signal switching, fail-safe setups, and automated control sub-systems. They’re also used in automotive PCB relays, such as 5-pin SPDT switches, where reversing or alternate routing is needed.

DPST – Double Pole Single Throw Relays

DPST relays control two separate circuits simultaneously with a single actuation. These are useful in AC coil applications and industrial machinery where parallel switching of power and control lines is required.

DPDT – Double Pole Double Throw Relays

DPDT relays are highly versatile, allowing two input signals to each switch between two output terminals. Found in boards in power systems, test devices, and control logic circuits, these relays are a go-to solution for differential relays or direction-sensitive devices.

Design Considerations for PCB Power Relays

Relay Integrations in Circuit Design

When integrating a relay into a PCB layout, engineers must consider:

- Contact and coil isolation

- Proper load circuit and primary circuit separation

- Thermal dissipation and ambient temperature ratings (e.g., -40°C to +85°C)

- Adequate distance between coil contacts to prevent arcing

- Correct design of relay circuits ensures safe, long-term functionality across all voltage applications.

Protection Mechanisms

Key protective features to look for in PCB power relays include:

- Ability to withstand voltage ratings for high-spike environments

- Flux proof and sealed contact structures to prevent flux ingress during soldering

- Use of auxiliary contacts for feedback and redundancy

- Mechanical contact sets with force-guided relays contacts for enhanced safety

- Standards such as IEC 61810-7 and RoHS compliance are essential for quality assurance and global compatibility.

Control Function Implementation

PCB relays are central to control functions such as:

- Switching between normal and backup power in power supplies

- Triggering alarms or safety disconnects in protective devices

- Handling high-voltage DC contactor events in storage system applications

- Managing signal flow in bus system actuators or AV devices

Advanced models now feature ceramic sealing technology, plug-in PCB terminals, and support for DC-1 utilization categories, offering robust performance across diverse applications.

Broader Integration with Safety & Automation Systems

PCB-mounted relays are a critical core of modern electrical systems, but are only one part of an integrated architecture. For any safe industrial system, these components will work alongside other critical components such as safety relays, safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are also key elements, managed by the logic structure of either the safety relay or safety PLC.

Advanced installations frequently incorporate safety non-contact switches, RFID switches, mechanical interlock switches, and/or solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Operational Insights

Soldering Techniques for PCB Relays

Proper soldering techniques are essential for the long-term stability of PCB power relays. Most miniature relays are flux-proofed or sealed to protect internal mechanisms during wave or reflow soldering.

Key tips include:

- Use bifurcated terminals or plug-in PCB terminals for consistent joints

- Maintain recommended preheating and cooling cycles to prevent internal component stress

- Avoid excessive soldering time to reduce contact resistance and preserve coil integrity

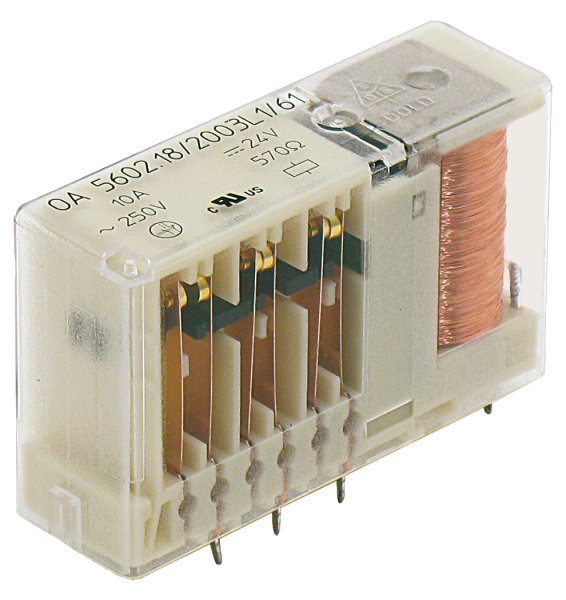

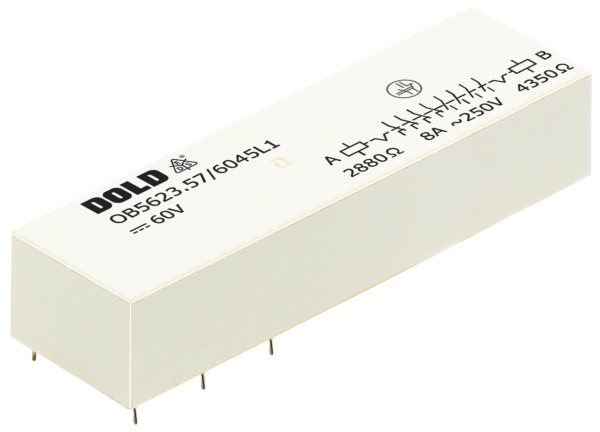

For high-current PCB relays, follow relay-specific temperature profiles found in datasheets (e.g., DOLD PCB Relay OA5602.54/2063L1/61 DC24V).

Testing Procedures for Reliability

To ensure reliability and consistent switching performance, manufacturers recommend:

- Mechanical life testing: repeated switching to test for wear

- Electrical endurance testing: verifying switching capability under load

- Measurement of contact resistance, withstand voltage, and coil power consumption

- Verifying response time, contact bounce, and insulation resistance

These procedures confirm that the relay meets safety standards such as IEC 61810-7 and is safe for use in critical load circuits.

Safety Approvals and Standards

Leading relays meet international safety approvals including:

- UL, VDE, TUV certifications

- RoHS compliant construction

- Adherence to IEC/EN 61810-7, IEC 60947, and other functional PCB relay criteria

These ensure safe operation in high-voltage environments, with standardized design criteria for manufacturers and installers.

Applications of PCB Power Relays

Industrial Applications

PCB power relays are essential in control cabinets, automation systems, electronic manufacturing, and machinery operation. Their ability to safely switch power allows them to control:

- Electric motors, solenoids, and contactors

- Distribution boards and panel-mounted systems

- HVAC and process control

They’re also frequently used in force-guided relay contact configurations for added safety.

Household Applications

In home electronics, PCB relays are found in:

- Washing machines, microwaves, water heaters, and air conditioners

- AV devices and smart control panels

- Compact and low-power relays ensure quiet operation, long lifespan, and thermal efficiency

Energy Market Applications

In renewable and energy storage sectors, PCB relays control:

- DC switching in solar inverters

- Load disconnection in energy meters

- Power routing in BESS (battery energy storage systems)

Relays which can withstand high voltage, have a low contact resistance, and have certified safety approvals are crucial for these applications.